-

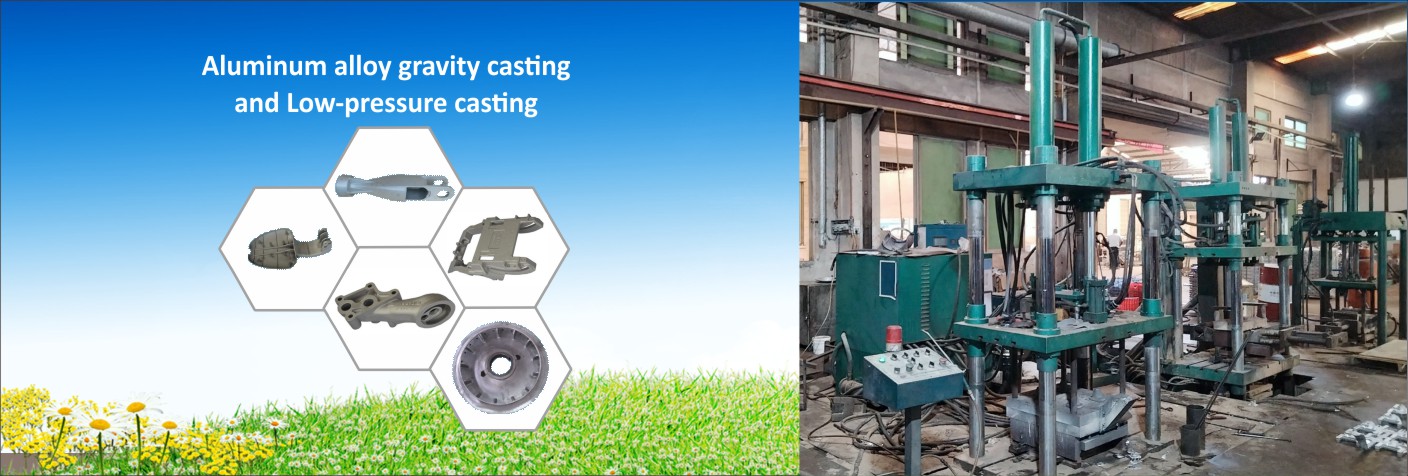

Aluminium Die Casting

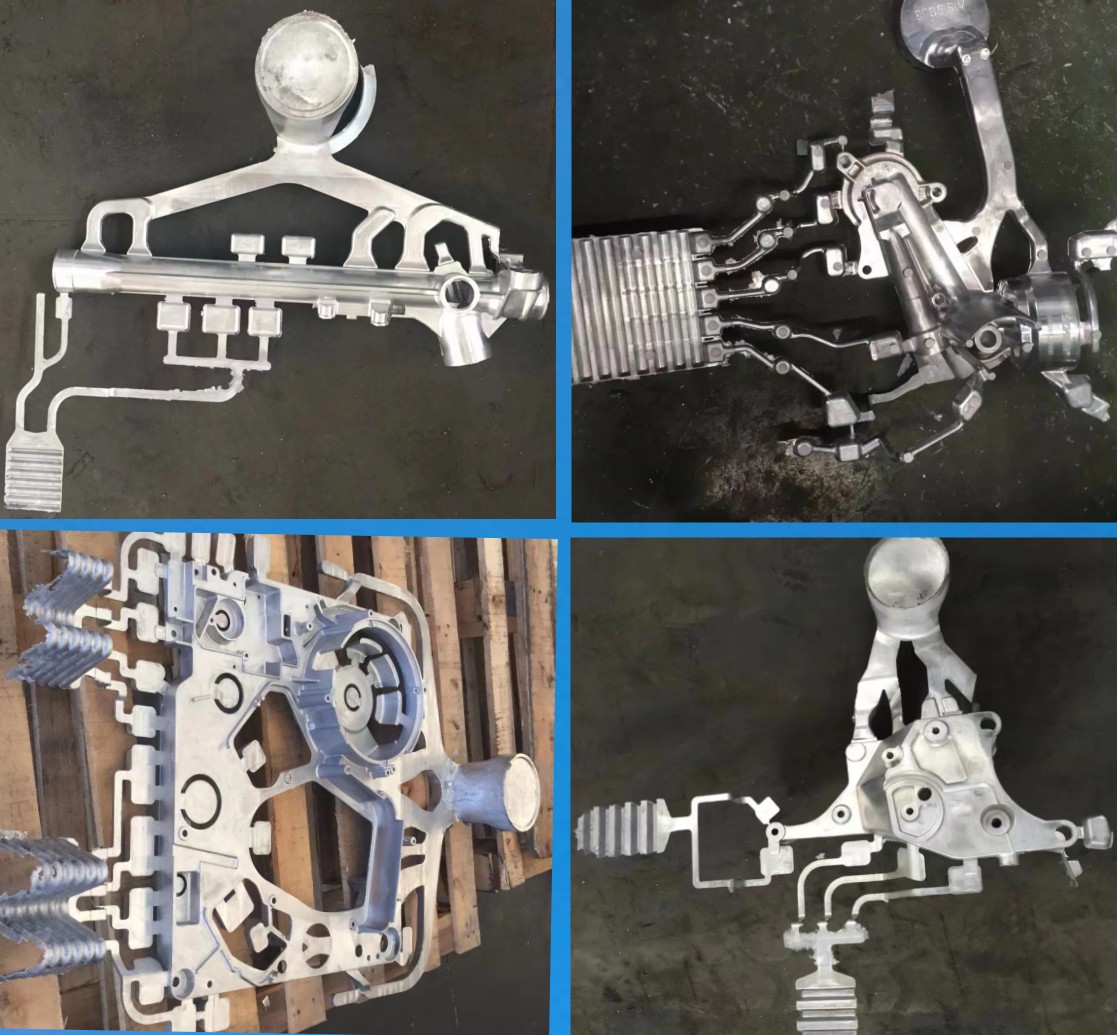

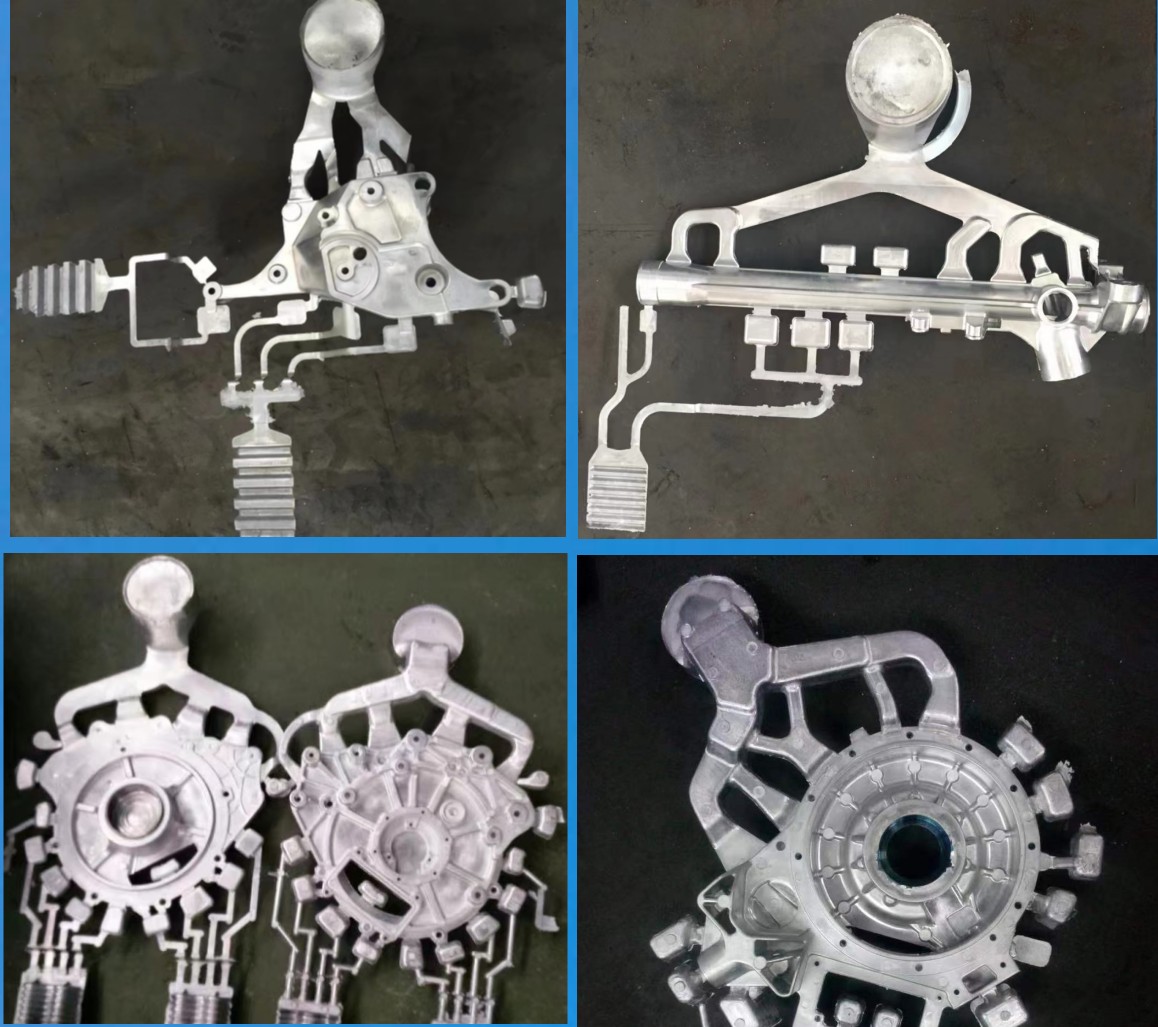

Aluminum alloy die castings refer to pure aluminum or aluminum alloy equipment components obtained through casting processing. Generally, sand molds or metal molds are used to pour molten aluminum or aluminum alloys into the mold cavity, resulting in various shapes and sizes of aluminum parts or aluminum alloy parts, which are commonly referred to as aluminum die castings.Products made with various brands have a wide range of uses, such as automotive parts, various household items, and industrial machine parts.

Cast aluminum alloy has some advantages that other castings cannot compare with, such as aesthetics, light weight, and corrosion resistance, making it widely favored by users. Especially since the lightweight of automobiles, cast aluminum alloy castings have been widely used in the automotive industry.

Casting aluminum alloy castings have numerous advantages, making them the development direction of the casting industry and one of the most favored casting products for procurement customers. In the future, with the progress of aluminum alloy casting technology, it will showcase its charm on a larger stage.

All our workbenches have automatic mold lubrication robots.

All our workbenches are made of raw materials from the fully automatic material packaging system, seven of which have quantitative furnaces.Our production is realized by eight 6-axis casting robots, which work according to the unit system and provide the most affordable price advantage and the highest quality standard for large quantities of parts orders.Dongguan Mindrad our goal is to continuously improve our efficiency and price advantage by making all our workbenches suitable for the battery system in the near future.